OWNERSHIP AND PERMITTED USE OF THE WEBSITE

The website, including all content, headings, images, graphics, button icons, scripts, presentation and arrangement, information video and audio is the property of Motoxparts and others and is protected by New Zealand and international copyright. The website is made available for lawful, personal use only. You may print pages from the website provided you do not modify pages and do not remove any notices or disclaimers. The website and its content may not be copied, imitated, reproduced, republished, uploaded, posted, transmitted, catalogued or distributed in any way without prior approval from Motoxparts.

Visitors to this website assume all responsibility and risk for the use of this website. Information published on this website is provided without charge as a convenience to visitors to be used for informational purposes only. Nothing in this website constitutes a recommendation or endorsement of any item, product or brand.

In no event shall Motoxparts be liable for any special ,directly, indirectly incidental or consequential damages or any other damages of any kind resulting from whatever cause including but not limited to loss of use, loss profits, or loss of data or otherwise arising out of or in any way in connection with use of or inability to use the information or materials on or accessed through the Motoxparts website.

THIRD PARTY SITES.

Motoxparts may from time to time provide links and pointers to Internet sites maintained by third parties ("third party sites") and it may from time to time provide materials from third parties on this Web Site. These third party sites and any third party materials are provided for your convenience only. Motoxparts does not operate or control in any respect any information, products or services available on these third party sites and Motoxparts is not responsible for their content. Motoxparts makes no representations whatsoever concerning the content of these sites and the fact that Motoxparts has provided a link to such sites is not an endorsement, authorization, sponsorship, or affiliation by Motoxparts with respect to such sites, its services, the products displayed, its owners, or its providers. You access these sites at your own risk.

MISPRINTS, ERRORS, OMMISSIONS, PRODUCT AVAILABILITY AND PRICES

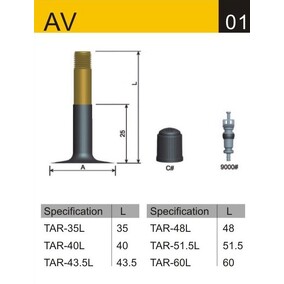

Motoxparts makes every effort to ensure the accuracy of information on its website. However typographical mistakes, inaccuracies (e.g. in prices or technical specifications) or other errors may sometimes occur. Motoxparts does not warrant that any information on the website is accurate or complete. Motoxparts reserves the right to correct any error, inaccuracy, omission or misprint at any time without prior notice or liability.

If an error is made and a product is listed at an incorrect price Motoxparts Ltd shall maintain the right to refuse any order placed at the incorrect price. If the order has been confirmed and paid, Motoxparts will issue a credit in the amount of the incorrect price.

Note: We do not guarantee Motoxparts Ltd prices listed on other websites or price engines.

CHANGES TO THIS WEBSITE

Motoxparts may at its discretion change, discontinue, add, remove or suspend any parts of this website without any notice or liability to any person.

TERMINATION

Motoxparts may at its discretion and for its convenience immediately terminate, temporarily or permanently, your permission to use the website without any notice.

YOUR INFORMATION

Al information you provide through the website including name, email address, address, phone numbers, payment information and transaction -related information must be true, accurate, current and complete. Motoxparts will rely on the information and you will be solely responsible for all loss, damage and additional costs that you, Motoxparts or any third party incur as a result of your submission of false information or failure to update information.

YOUR PASSWORD

You are responsible for all actions taken with your user name, email address and password. Therefore we do not recommend that you disclose your password to any third parties. If you choose to share your user name, email address and password or your information with third parties, you are responsible for all actions taken with this information and therefore you should review that third party's privacy policy.

PRIVACY

Your personal information and contact details are used only for the purposes of facilitating a transaction with Motoxparts, or with your consent to provide you with ongoing information e.g. newsletter or special offers. Your information will not be shared, sold or given to other parties, except where legislation requires.

We may also collect and summarize customer information in a format that no longer identifies the individual for statistical purposes.

Your Implied Consent:

In some cases, your consent is implied if we ask you to provide personal information with a stated purpose. For example, we can only deliver the product you have purchased if you provide us with your address and phone number.

Your Express Consent:

In other cases, e.g. a mailing list, by joining you are giving us your express consent to use your personal information to advise you of products or services that may be of interest. You always have the opportunity to "opt out" of having your information used for this purpose.

Withdrawing Your Consent:

If you have "opted in" or subscribed to one of our newsletters or mailing lists, we will always provide you the opportunity to "opt out" or unsubscribe. For example, each email we send you will tell you how to decline further mail.

COOKIES

The Website may use "cookies", a technology that installs a small amount of information on a Website user's computer to permit the Website to recognise future visits using that computer. Cookies enhance the convenience and use of the website. For example, the information provided through cookies is used to recognize you as a previous user of the Website (so you do not have to enter your billing information every time), to offer personalized Web page content and information for your use, to track your activity at the Website, to respond to your needs, and to otherwise facilitate your Website experience. You may choose to decline cookies if your browser permits, but doing so may affect your use of the Website and your ability to access certain features of the Website or engage in transactions through the Website.